How to Use an Airless Sprayer Painting

Learn how to use an airless paint sprayer to paint faster with perfectly smooth results. We show you how the machine works, good painting techniques and how to avoid mistakes.

Airless paint sprayers: Pros and Cons

An airless sprayer simplifies painting in two ways: First, if you want to speed up a job that requires several gallons of paint, you can apply it twice as fast as with a roller or brush. And second, if you want a glass-smooth finish on woodwork or doors, the airless sprayer can lay the paint on flawlessly.

An airless sprayer works by pumping paint at a very high pressure, up to 3,000 psi, through a hose and out a tiny hole in the spray gun tip. The tip is designed to break up the paint evenly into a fan-shaped spray pattern of tiny droplets. Using different tips, you can spray thin liquids like stain, lacquer and varnish or thicker liquids like latex house paint. With a little practice, you can use an airless sprayer to apply a perfectly smooth finish on doors, cabinets and woodwork. And since an airless sprayer pumps paint directly from a can or 5-gallon bucket, you can apply a lot of material in a short time. This makes an airless sprayer particularly well suited for large paint jobs, like priming bare drywall in a new house or painting a 300-ft.-long privacy fence.

But before you get too excited about the benefits of spray painting, there are a few drawbacks to consider. First, the fine particles of paint don’t all stick to the surface. A large percentage of the paint ends up in the air, where it can drift and settle onto everything in sight. This means you’ll be wasting 20 to 40 percent of the finish, depending on the application. You’ll also have to take extra time to mask off and cover up everything you want to keep paint free. Outdoor painting is especially risky. Overspray can end up on your shrubs or roof, or drift with the wind onto your neighbor’s car.

The other downside is the extra time it takes to flush the paint from the pump and hose and clean up the spray gun. If you’re using your own sprayer, rather than a rental unit, you’ll also have to clean the filters and install special storage fluid. And if you’re spraying oil-based products, you’ll have to store or recycle a gallon or two of used solvents left over from the cleaning process. But despite these disadvantages, an airless can save you a lot of time on big paint jobs and allow you to get a finish that’s nearly impossible to get with a brush.

Sprayer set-up steps:

1. Exhaust all air in the pump.

Place the smaller prime tube in a waste pail and the suction tube in the bucket of strained paint. Turn the prime/spray valve to “prime.” Switch on the pump. Turn the pressure valve up until the pump starts. When the paint starts flowing from the prime tube, move it into the paint bucket.

Whether you rent or buy an airless sprayer, there are a few key setup points. All sprayers have a screen at the intake point. Make sure it’s clean. Most airless sprayers also have a removable filter near the pump and another one in the handle of the gun. Check both to make sure they’re clean, and plan to strain your paint through a mesh filter bag to remove lumps so they won’t clog the filters.

Before you can start spraying, you have to prime the pump. You may have to repeat this process if the paint in the bucket runs out while you’re spraying.

2. Fill the hose

Hold the gun (guard and spray tip removed) over the waste bucket and pull the trigger. Switch the valve to the “spray” setting. Let go of the trigger when paint is flowing in a steady stream from the gun. Lock the trigger and follow the “Pressure Relief Steps.”

Once the pump is primed, you’re ready to fill the hose with paint. Then lock the trigger and relieve the pressure before installing the tip guard assembly and inserting the tip.

Pressure relief steps

l Turn off the power switch.

l Turn the spray/prime valve to prime.

l Aim the gun against the side of the waste pail and pull the trigger to release the pressure.

l Engage the trigger lock.

3. Adjust the spraying pressure.

Turn on the pump and move the prime/spray lever to the “spray” position. Spray a strip of paint across a piece of cardboard to check the spray pattern. If the spray pattern has tails, the pressure is set too low. Turn up the pressure.

Too little pressure will result in an uneven spray pattern. And too much pressure causes excessive overspray and premature tip wear. Below photo shows how to dial in just the right amount. If you’re still getting “tails” or an uneven spray pattern even at maximum pressure, try using a tip with a smaller hole. If the spray pattern is round rather than narrow, the tip is worn and should be replaced.

4. Airless Spraying technique

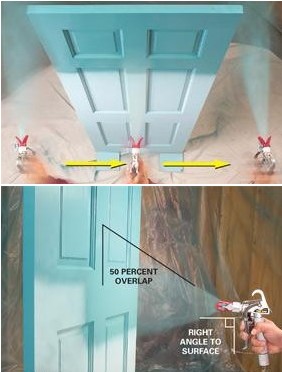

Squeeze the trigger before you reach the edge of the door. Move the sprayer quickly across the door, keeping it parallel to the surface. Release the trigger when the sprayer is past the opposite edge of the door.

Below photos show the correct spray techniques. Here are a few key points:

- Plan your spraying sequence before you start. On doors, for example, spray the edges first. Then spray top to bottom. Then spray at right angles side to side.

- Squeeze the trigger while the gun is off to the side, and then move it onto the work.

- Move the gun parallel to the surface, not in an arc.

- Keep the gun perpendicular to the surface, not tilted.

- Move fast to prevent runs. Several thin coats are better than one thick one.

- Overlap your strokes about 30 to 50 percent.

paint the door with airless sprayer

5. Clear a clogged tip

If paint stops flowing or sputters from the gun, the tip may be clogged. Twist the tip 180 degrees. Point the gun at a scrap of paper and squeeze the trigger to clear the clog. Rotate the tip 180 degrees to point it forward again and spray a test strip onto the scrap.

Most spray problems are a result of clogged airless spray gun filters, a clogged tip, or a pump that’s either leaking at the packing or has stuck ball-check valves. Careful cleaning and proper maintenance will prevent most of these troubles.

Other problems, such as runs and uneven coverage, are caused by using the wrong tip size or by a lack of spraying experience. As with most construction tasks, practice is the key to success.

6. Clean the sprayers:

When you are finished painting, thoroughly clean the sprayer. All the paint must be cleaned out after each use.

Once you have completed your paint spraying task, fill a bucket with paint thinner if you painted with oil-based paint, or water if it was latex-based. Remove the intake hose from the paint sprayer and place it in your bucket of liquid. Trim the length of your old paintbrush to 1 inch—you will need this later. Put on your gloves and gather the rest of your equipment before you begin.

Any left over paint in your gun can be saved by shooting the gun into the paint can to release any paint still left within it. Be careful not to release any paint thinner into the can. Taking an empty second bucket, spray the remaining liquid until you get a clear and clean spray.

motor-power 1500W

max-tip-size 0.023"

flow-rate 2.5L/min

Motor power 1000w

Max. tip size 0.021"

Flow rate 1.8L/min

motor-power 1500W

max-tip-size 0.023"

flow-rate 2.5L/min